|

|

| Home |

About Speaker DriversAs I stated in earlier chapters, a good sound will be always present, when distortion mechanisms are absent. The same holds true for speakers. Unfortunately I have the feeling, that today's designers of speaker drivers seem to have absolutely no idea, what they are doing. In the early days, a speaker manufacturer or designer listened to his products and if it did not sound good, it was certainly regarded as wrong. Today they rely on measurements in anechoic chambers and many of them respect their own listening less than their futile measurements. Also the technical specification of speaker drivers gives you lots of useless numbers, but not any information of the most important construction features. In fact, there are only two real distortion mechanisms concerning speakers, but you will not be able to find any contemporary speaker driver, which is designed in order to avoid those simple distortion mechanisms (there are very rare exceptions).

1) Wrong materialsThe speaker cone and coil-former material is much more important to the sound than the geometry and basket of the speaker. The Mother-of-Tone material for cones and coil formers is PAPER. It is nothing short of ridiculous to make a speaker with an aluminium or titanium, polypropylene or ceramic cone. It doesn't work. Well, some think it does ;-) The only thing unsuited cone materials can do is to nerve you. Speakers that employ those unsuited materials must have very complex crossover networks in order to keep you from continued vomiting. Note: On HF compression drivers, aluminium and titanium diaphragms can still sound good, when the horn is made of a decent material, as sound is reflected inside the horn many times and adapts the vibrational character of the horn-material -> see Mother-of-Tone chapter. You are still able to get speaker drivers with non-plasticized paper cones, but most of them will have a voice-coil made of aluminium or plastic (i.e. Kapton). Aluminium and Kapton are very good for heat dissipation and you can make cheap hi-wattage speakers with those materials, but what's the need of hi-wattage, if you can't bear to listen to the shit?

Above is a view inside a aluminium voice-coil former of a otherwise excellent speaker construction. Although capable of high power dissipation, a speaker employing an aluminium voice-coil former will always sound like sheet metal, which can be useful if you will be using it exclusively for steel-guitar ;-)

See above a Kapton voice coil former. Better than aluminium, but never natural sounding. Actually it sounds as it looks... like plastic.

A Nomex voice-coil former (above) yields a high level of sound quality plus a much higher heat dissipation compared to paper. For many speaker applications Nomex is the ideal voice-coil matierial (especially for bass or mid drivers). Unfortunately it is rarely used today (except for some famous Celestion guitar speakers). When it comes to highest sound quality (and lowest power dissipation) paper is the way to go. See below the cone and voice-coil former of a perfectly constructed 1950's radio speaker.

Other speaker drivers that still employ paper cones AND paper voice-coil formers are Lowther (beware of hi-ferric ;-), Fostex FE series and some cheap chinese speakers (see below).

The drivers above feature small paper-voice-coils, paper cones, re-fitted foam surrounds, spruce-phase-plugs, small magnet and small power-dissipation. As they have no distortion-mechanism, they are used without crossover. The paper HF driver at the top is fed through a capacitor.

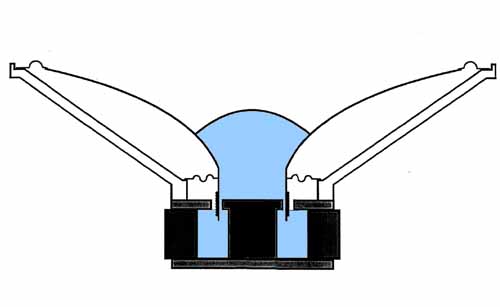

2) CavitiesThe second distortion mechanism for speaker drivers is the presence of cavities. Cavities create resonances and can totally mess up the performance of otherwise decently made speaker drivers. See the below illustration of cavities (blue) that can be found in a contemporary speaker:

The very majority of today's speakers use ferrite magnets that leave a relatively large hollow space between the pole piece and the magnet. As each enclosure or cavity has resonant modes, a cavity behind the voice coil (in the magnet structure) will create a distortion. The character of this distortion is a trashy peaky metal sound. This distortion speaks through the voice-coil and is easily identified, as it results in peaks in the frequency response. Drivers using Alnico and Neodynium magnets typically have no or very small cavities in the magnet structure -> see below a positive example of how a magnet structure should look:

There's another cavity in front of the voice-coil between the pole-piece and the dust-cap. This is also an enclosure which will generate a resonance frequency peak in the speaker response. It will also prevent accurate signal reproduction of the speaker. The character of this distortion depends largely on the size of the dustcap (the smaller the better) and the voice-coil-former material. A dustcap will in any case fuzz the sound. It will prevent a otherwise focused clean sound production. If the cavities are so small that their resonance frequencies are above 20kHz, the problem is gone to a large degree. A phase plug (preferrably lacquered wood) is a simple and effective measure to eliminate the front cavity as shown below with a modified Fostex FE164.

If dust protection is needed, this can be accomplished with a sound-permeable material (i.e. textile gauze) as found still today i.e. on the Celestion Vintage 30 and Greenback guitar speakers (guess why). So let's summarize: Any speaker that prevents cavities in front or behind the voice coil and employs paper for the cone AND the voice-coil-former will sound good. ANY SPEAKER !! That was all. Is it really so EASY to make a great sounding speaker ? YES !!!

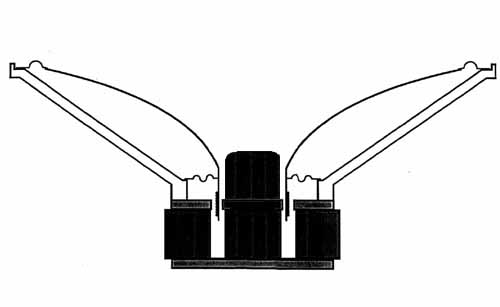

A perfect Speaker DriverA perfect speaker driver employs a non-plasticized paper cone, and a paper or nomex voice-coil former. It uses any kind of magnet, provided that there is no cavity in the magnet structure. A perfect speaker driver also has no dust-cap, but a phase plug (preferably made of wood), that fills the voice-coil cavity. If a dust-prevention is needed, a sound-permeable material should to be chosen in combination with a short phase plug. See below, the corrected speaker construction, which avoids cavities:

The suspension and voice-coil diameter is chosen with respect to the desired frequency response. A speaker as described above, is not necessarily expensive to manufacture, and it also needs no elaborate crossover network, as distortion-mechanisms have been avoided.

Altmann Micro Machines … Dipl.-Ing. Charles Altmann… Erlenstrasse 15… 42697 Solingen… Germany phone +49-212-233-7039… email

|